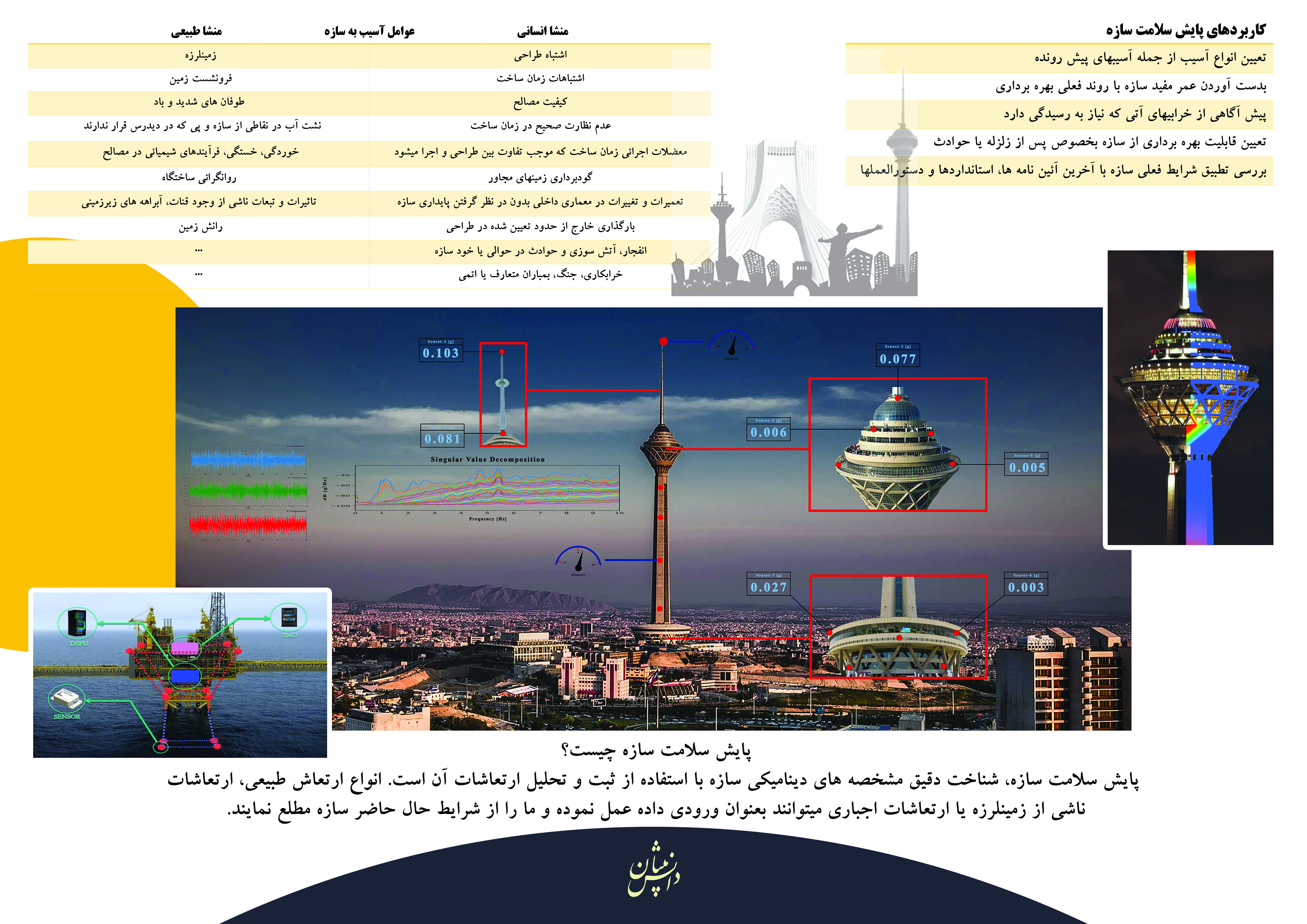

Equipping high-rise towers, administrative buildings, hospitals, commercial and office centers, malls, and hotels with this system enables real-time awareness of the structure’s condition during a crisis, without the need for emergency evacuation or months-long stability assessments, allowing the best decisions to be made based on the latest structural data.

Given today’s risks, including earthquakes, subsidence, war, explosions, fires, and wear due to aging structures, equipping buildings with advanced sensors and monitoring the results on a mobile device provides a reliable option for decision-making in critical situations, reducing stress and minimizing the arduous efforts associated with emergency evacuations.

English

English  Spanish

Spanish  Turkish

Turkish  Arabic

Arabic  Farsi

Farsi